In modern healthcare systems, the disposal of medical waste has become an important and urgent issue. Medical waste contains a large amount of pathogens, harmful chemicals, and other pollutants. If not handled properly, it may pose a serious threat to the environment and public health. In response to this challenge, medical waste incineration equipment has emerged as a key means of treating medical waste.

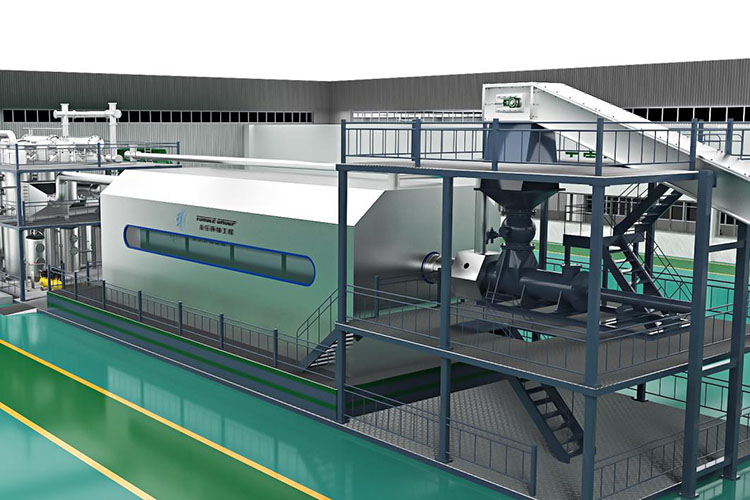

The medical waste incineration treatment equipment mainly consists of several key components, including the feeding system, incinerator, burner, exhaust treatment system, thermal energy recovery system, and control system. These parts work together to ensure that waste can be efficiently and safely incinerated. The feeding system is the first checkpoint of medical waste incineration treatment equipment, responsible for safely transporting waste from the collection point to the incinerator. The feeding system usually includes waste collection, storage, and transportation devices to ensure that waste is transported in a closed environment and reduce the risk of secondary pollution. As the core of the equipment, the incinerator is usually divided into a primary incineration chamber and a secondary incineration chamber. The primary incineration chamber is used for the main combustion of waste, with a temperature generally above 850 ℃, to decompose the organic matter in the waste into gas and ash. The secondary incineration chamber is used for thorough combustion of exhaust gas, with a temperature above 1100 ℃, to ensure that all harmful substances are completely decomposed. The burner provides the heat source required for incineration, ensuring that waste is fully decomposed at high temperatures. The design and performance of the burner directly affect the incineration efficiency and overall operation of the equipment.

The smoke generated during the incineration process needs to undergo strict treatment. The smoke exhaust treatment system includes dust collectors, washing towers, and other smoke purification devices to remove harmful gases and particulate matter, ensuring that emissions meet environmental standards. The high-temperature heat generated during the incineration process can be utilized through a heat recovery system for power generation or heating. This not only reduces energy waste, but also improves resource utilization efficiency. Modern medical waste incineration treatment equipment is usually equipped with advanced control systems, which ensure the safe and efficient operation of the equipment through automated control and monitoring.

The working process of medical waste incineration equipment includes multiple steps such as waste collection and feeding, primary incineration, secondary incineration, smoke exhaust treatment, heat recovery, and ash treatment. Medical waste is first collected and stored in specialized containers, and then transported to the incinerator through a feeding system. This process requires strict control to ensure that waste does not leak or pollute the environment. Waste undergoes initial combustion in the primary incineration chamber, where high temperatures decompose organic matter into gas and ash. The design and operation of the primary incineration chamber directly affect the efficiency of incineration and the effectiveness of subsequent treatment. Incomplete combustion gases and particulate matter enter the secondary combustion chamber and undergo secondary combustion at higher temperatures to ensure that harmful substances are completely decomposed. This process is crucial for ensuring the complete harmless treatment of exhaust gases. The smoke generated by combustion is purified through a smoke exhaust treatment system to remove harmful gases and particulate matter. The performance of the smoke exhaust treatment system directly affects the environmental protection effect of the equipment, and advanced technology and equipment need to be adopted. The heat generated during the incineration process can be utilized through a heat recovery system for power generation or heating. This not only reduces energy waste, but also improves resource utilization efficiency. The ashes after combustion need to be collected and processed, usually solidified and buried to reduce their impact on the environment.

Medical waste incineration equipment has significant advantages in treating medical waste, but also faces some challenges. Incineration can greatly reduce the volume of medical waste and decrease the need for landfilling. High temperature incineration can effectively kill pathogens and reduce the risk of disease transmission. By utilizing the heat energy generated during the incineration process, energy recovery and utilization can be achieved, thereby improving resource utilization efficiency.

With the increasing environmental requirements and technological advancements, the development trend of medical waste incineration equipment includes improving energy efficiency, strengthening emission control, and intelligent management. Through technological improvements, incineration efficiency and heat recovery rate can be improved, energy waste can be reduced, and resource utilization efficiency can be enhanced. Develop more advanced flue gas purification technologies to reduce the emission of harmful substances and ensure compliance with stricter environmental standards. Introducing intelligent control systems to achieve automation and remote monitoring of equipment, improving operational efficiency and safety.

In summary, medical waste incineration equipment is an effective means of treating medical waste. Through reasonable use and management, it can effectively reduce environmental pollution and ensure public health. In the future, with the continuous advancement of technology and the improvement of environmental protection requirements, medical waste incineration equipment will continue to play an important role in providing solid guarantees for health and the environment.

Yongle Environmental Protection is mainly engaged in the research and development, production and sales of complete sets of technical equipment for organic solid waste disposal and comprehensive utilization. Production and manufacturing, domestic waste treatment equipment, tire pyrolysis equipment, medical waste disposal equipment, hazardous waste disposal equipment, and achieve efficient and comprehensive utilization of resources through independently developed low-temperature anaerobic pyrolysis equipment technology solutions.

Tags:Advantages and Development Trends of Medical Waste Incineration Equipment,medical waste incineration treatment equipment ,Yongle Group,YONGLE GROUP

Latest news

Latest news