Medical waste disposal equipment plays a crucial role in modern medical waste management. With the improvement of medical level and the increase of medical institutions, the issue of medical waste disposal has become increasingly urgent. These wastes often contain pathogens, chemicals, and other harmful substances, which, if not handled properly, may pose a serious threat to public health and the environment. Therefore, the role of medical waste treatment equipment is particularly important. These devices effectively treat medical waste through various technological means to ensure that its harm to the environment and human health is minimized during the treatment process.

Firstly, the first step in medical waste disposal is to classify the waste. The emergence of classification devices enables effective sorting of medical waste based on its properties. Medical waste is classified into recyclables, hazardous substances, and general waste through automatic sorting systems or manual sorting lines. This process can not only improve the efficiency of subsequent processing, but also minimize the possibility of secondary pollution.

After classification, medical waste is usually sent to disinfection equipment for preliminary treatment. The main function of disinfection equipment is to kill pathogens in waste and reduce their infectivity through high-temperature steam, microwave, or chemical substances. Although disinfected medical waste has been preliminarily treated, its volume and shape are still not suitable for subsequent processing, so it needs to be crushed and compressed.

The crushing equipment played a crucial role in this stage. Medical waste is processed into small pieces in crushers or shredders, greatly reducing its volume and facilitating subsequent processing steps. By crushing, the volume of waste is reduced, while also increasing its surface area, making subsequent treatments such as incineration or high-temperature sterilization more effective.

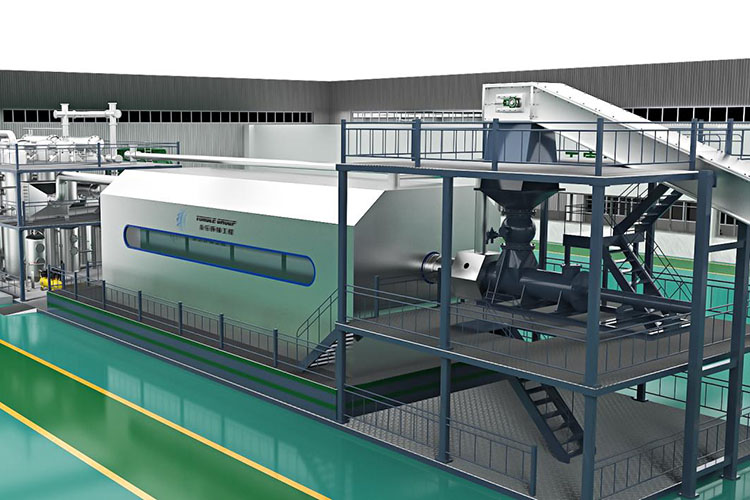

Incineration equipment is an important part of medical waste treatment. The crushed medical waste is sent to an incinerator or rotary kiln and completely destroyed through high-temperature incineration. This process not only effectively reduces the volume of waste, but also kills all pathogens and harmful substances in the waste. The residue generated after incineration is usually harmless and can be safely buried or further processed. However, during the incineration process, some harmful gases may be produced, and if left untreated, these gases may have an impact on air quality.

In order to solve this problem, gas processing equipment has emerged. These devices use technologies such as flue gas purification, activated carbon adsorption, and acid gas washing to treat harmful gases generated during incineration, ensuring that the emitted gases meet environmental standards. In this way, the incineration process can not only effectively treat medical waste, but also minimize its impact on the environment.

In addition to incineration, high-temperature and high-pressure sterilization is also an important means of medical waste disposal. High pressure sterilizers and pyrolysis furnaces ensure the complete elimination of pathogens that may remain in waste by sterilizing under high temperature and pressure. This treatment method is suitable for medical waste that is not suitable for incineration, such as specific chemical waste or waste containing metal components. The waste after high-temperature and high-pressure sterilization can be further compressed and packaged for convenient transportation and disposal in the future.

During the entire process of medical waste disposal, a large amount of wastewater needs to be treated. These wastewater mainly come from disinfection and cleaning processes, and if discharged directly, it will cause pollution to the water source. The sewage treatment equipment plays a crucial role here. These devices remove harmful substances from wastewater through various methods such as biological filtration, physical precipitation, and chemical treatment, ensuring that the discharged water quality meets environmental standards.

In order to ensure the safety and effectiveness of the entire medical waste disposal process, monitoring and control systems are widely used. These systems can monitor the operational status of various processing stages in real time, ensure the normal operation of equipment, and issue alerts in a timely manner when problems occur. In addition, the environmental monitoring system also plays an important role in the entire treatment process, as it can detect the content of harmful substances in the air, water quality, and soil, ensuring that the treatment process does not cause secondary pollution to the surrounding environment.

Overall, medical waste treatment equipment converts hazardous medical waste into safe and harmless substances through a series of complex and precise operations. They not only protect people's health, but also provide guarantees for the sustainable development of the environment. With the continuous advancement of technology, medical waste treatment equipment will become more efficient and environmentally friendly, opening up broader prospects for the treatment and disposal of medical waste.

Yongle Environmental Protection is mainly engaged in the research and development, production and sales of complete sets of technical equipment for organic solid waste disposal and comprehensive utilization. Production and manufacturing, domestic waste treatment equipment, tire pyrolysis equipment, medical waste disposal equipment, hazardous waste disposal equipment, and achieve efficient and comprehensive utilization of resources through independently developed low-temperature anaerobic pyrolysis equipment technology solutions.

Tags:Introduction to medical waste treatment equipment and its environmental significance,medical waste treatment equipment,Yongle Group

Latest news

Latest news