As an important recycling and processing equipment, waste tire refining equipment can thermally decompose waste tires into fuel oil, carbon black, and combustible gases, achieving resource reuse. Every year, a large amount of waste tires are generated, and traditional landfill and incineration methods not only pollute the environment, but also cause resource waste. Therefore, utilizing advanced refining equipment for pyrolysis treatment can not only effectively reduce environmental pollution, but also create economic value.

In recent years, the demand for renewable fuels in the market has been increasing. Refining waste tires into oil can produce fuel oil, which has a strong market demand as an alternative energy source for industrial boilers, power plants, and ship fuels. Investing in waste tire refining equipment requires consideration of multiple aspects such as equipment procurement, site construction, raw material acquisition, and operating costs.

The price of waste tire refining equipment varies depending on the model, production capacity, and configuration, and the market price generally ranges from 200000 to 2 million RMB. Fully automated equipment has a higher cost, but is easy to operate and has higher production efficiency. It is recommended that the factory area be at least 1000 square meters, taking into account the cost of land leasing or purchase. At the same time, the construction of factory buildings, installation of equipment, and other infrastructure also require certain investment. In terms of raw materials, the purchase price of waste tires varies depending on the region and quality, generally ranging from 500 to 1500 yuan/ton. Large scale procurement can reduce costs.

The operation of the equipment involves energy consumption such as electricity and fuel, and the estimated energy cost per ton of tire processing is about 100 to 300 yuan. At the same time, it is necessary to hire technical personnel and workers, and the wage cost depends on the local labor market. After pyrolysis, about 40% -45% of fuel oil can be produced per ton of waste tires, and the market price is generally between 3500 and 5000 yuan/ton, depending on market conditions. Carbon black can be used in the production of rubber products, inks, coatings, etc. About 30% of carbon black can be produced per ton of waste tires, with a market price ranging from 500 to 1500 yuan/ton. In addition, the combustible gases generated during the pyrolysis process can be used for self combustion, reducing fuel consumption and improving economic efficiency. The steel wire in the tire can be recycled and reused, with about 10% -15% of the steel wire being recycled per ton of tire. The market price ranges from 800 to 2000 yuan/ton.

Incineration equipment plays an important role in the components of waste tire refining equipment. An efficient incinerator can effectively treat the waste gas and solid residue generated during the pyrolysis process, ensuring environmental compliance. Modern incineration equipment usually adopts high-temperature cracking and secondary combustion technology to fully burn harmful gases and reduce pollutant emissions. At the same time, some incineration equipment is also equipped with flue gas purification systems, such as activated carbon adsorption devices, water curtain dust removal systems, and SCR denitrification technology, to ensure that exhaust emissions meet environmental standards. In addition, some advanced equipment also adopts a heat recovery system to use the heat generated during the incineration process for heating or power generation in the factory area, improving overall energy utilization efficiency.

The prices of fuel oil and carbon black are greatly affected by the market. It is recommended that investors establish stable sales channels and improve their risk resistance. Choose mature and stable refining technologies and equipment to avoid production interruptions or economic losses caused by equipment failures. The investment in waste tire refining equipment has good market prospects and high profit margins, but investors need to comprehensively evaluate the market, costs, and risks to ensure the feasibility of the project. Reasonably planning investment strategies and selecting appropriate equipment and process flows will help achieve long-term stable profits.

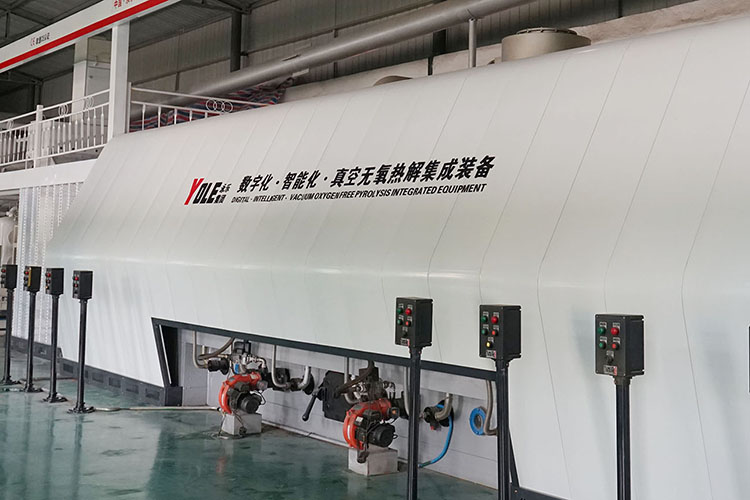

Yongle Environmental Protection is mainly engaged in the research and development, production and sales of complete sets of technical equipment for organic solid waste disposal and comprehensive utilization. Production and manufacturing, domestic waste treatment equipment, tire pyrolysis equipment, medical waste disposal equipment, hazardous waste disposal equipment, and achieve efficient and comprehensive utilization of resources through independently developed low-temperature anaerobic pyrolysis equipment technology solutions.

Tags:Investment Guide for Waste Tire Refining Equipment,Tire Refining Equipment,YONGLE GROUP

Latest news

Latest news