The return on investment of waste tire refining equipment is a core issue of concern to many investors. With the increase in environmental awareness and the demand for resource reuse, the treatment and reuse of waste tires has gradually become an industry with potential. However, evaluating the return on investment of this project requires in-depth analysis of multiple factors to provide a basis for investment decisions.

First, the initial investment is an important factor affecting the return on investment. The cost of purchasing waste tire refining equipment, installation costs, and site rental costs are all initial expenses that need to be considered. Generally speaking, the price of equipment varies greatly, depending on its technical level, production capacity and brand. Therefore, when choosing equipment, investors should carefully evaluate the products of different manufacturers and choose cost-effective equipment to reduce the initial investment cost.

Next, operating costs are another key factor affecting the profitability of the project. During the operation process, labor, energy consumption, and the purchase costs of raw materials (i.e., waste tires) all directly affect the overall cost. The source and purchase price of waste tires will change with market fluctuations, so it is crucial to establish a stable supply channel. In addition, the maintenance and management costs of the equipment cannot be ignored. Regular maintenance can not only extend the service life of the equipment, but also improve production efficiency and further reduce the unit product cost.

In the process of refining waste tires, the market price of the final product is an important indicator directly related to the return on investment. The products available after refining include oil, carbon black and other usable by-products. The market price of the product is affected by supply and demand, industry competition and policy factors. Therefore, investors need to pay close attention to market trends and adjust production strategies in a timely manner to ensure a reasonable sales price. At the same time, broadening sales channels and finding more customer groups are also effective ways to increase profits.

The level of production efficiency will also significantly affect the return on investment. The production capacity and operating efficiency of the equipment are important factors in determining the output. Efficient equipment can process more waste tires per unit time, thereby increasing output and reducing the production cost of each unit product. Therefore, when selecting equipment, investors should give priority to those equipment with advanced technology and high stability. In addition, reasonable arrangement of production processes and optimization of operation management can also help improve overall production efficiency and achieve better economic benefits.

In addition to the above factors, policy support cannot be ignored. The policies of local governments on environmental protection projects and waste material recycling may affect the return on investment. For example, some regions provide financial subsidies, tax exemptions or loan concessions for environmental protection projects. These policies will directly reduce investment risks and enhance the attractiveness of projects. When planning projects, investors should understand local policies and regulations in detail so as to make full use of relevant preferential policies.

Finally, market demand is another important factor in determining investment returns. With the increasingly stringent environmental regulations and the enhancement of public environmental awareness, the market demand for refined products has gradually increased. Therefore, when evaluating projects, investors should fully consider the changing trend of market demand and make reasonable investment decisions based on market research results.

In summary, the investment return analysis of waste tire refining equipment needs to comprehensively consider multiple factors such as initial investment, operating costs, product prices, production efficiency, policy support and market demand. The reasonable investment return cycle is generally between 2 and 5 years, and the specific situation needs to be adjusted according to market conditions, project scale and management level. Through comprehensive market analysis and financial forecasting, investors can more clearly evaluate the feasibility of the project and lay the foundation for achieving a considerable return on investment.

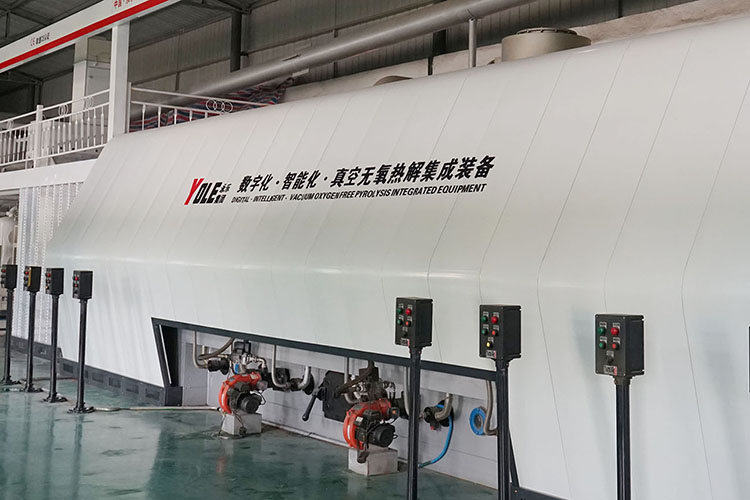

Yongle Environmental Protection is mainly engaged in the research and development, production and sales of complete sets of technical equipment for organic solid waste disposal and comprehensive utilization. Production and manufacturing, domestic waste treatment equipment, tire pyrolysis equipment, medical waste disposal equipment, hazardous waste disposal equipment, and achieve efficient and comprehensive utilization of resources through independently developed low-temperature anaerobic pyrolysis equipment technology solutions.

Tags:Return on investment of waste tire oil refining equipment,waste tire oil refining equipment,YONGLE GROUP

Latest news

Latest news