Sludge treatment equipment is an indispensable part of the modern sewage treatment process. Its main purpose is to reduce the volume of sludge, reduce the water content, and achieve harmlessness, stabilization and resource utilization of sludge. With the continuous improvement of environmental protection requirements, there are many types of sludge treatment equipment, each with its own characteristics, to meet different treatment needs. The following will introduce common sludge treatment equipment and its characteristics.

First of all, sludge dewatering equipment is one of the most basic sludge treatment equipment. Its main function is to remove moisture from sludge by various mechanical means, thereby reducing the volume of sludge for subsequent treatment or transportation. Common dewatering equipment includes belt filter press, centrifuge and plate and frame filter press.

Belt filter press is a common continuous dewatering equipment, which removes moisture from sludge by gravity and mechanical extrusion. The equipment has the advantages of simple operation and continuous operation, and is particularly suitable for treating large amounts of sludge. The centrifuge separates solids and water in the sludge through the centrifugal force generated by high-speed rotation, which is suitable for treating sludge with high water content. The plate and frame filter press uses pressure to squeeze out the water in the sludge. Although its dehydration effect is good, its efficiency is relatively low and it is suitable for intermittent operation. In general, the advantage of sludge dehydration equipment is that it can greatly reduce the volume of sludge and reduce transportation and processing costs, but different types of equipment vary in efficiency and cost.

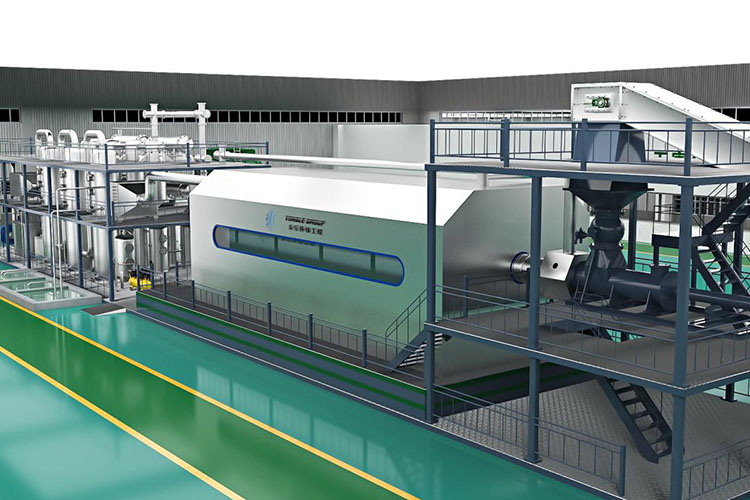

Sludge drying equipment is an important equipment to further reduce the moisture content of sludge. It evaporates the water in the sludge by heating or other means, thereby further reducing the volume of sludge. Common drying equipment includes disc dryers, paddle dryers and drum dryers. The disc dryer heats the sludge by heat conduction and is suitable for small and medium-sized sludge treatment plants, while the paddle dryer heats the sludge by steam in the jacket to achieve rapid drying, which is suitable for large-scale sludge treatment. The drum dryer combines drum rotation with hot air and is suitable for processing large amounts of sludge.

The advantage of sludge drying equipment is that it can effectively reduce the moisture content of sludge, making sludge treatment more convenient. At the same time, the dried sludge can also be used as organic fertilizer, fuel and other resources, increasing economic benefits. However, the energy consumption of sludge drying equipment is high, and the equipment investment cost is relatively large. Therefore, it is necessary to comprehensively consider the treatment needs and cost investment when choosing.

Sludge incineration equipment is used to treat organic matter in sludge by high-temperature combustion. The ash produced during the incineration process can be used in building materials and other fields. Fluidized bed incinerators, rotary incinerators and multi-stage incinerators are common types of sludge incineration equipment. Fluidized bed incinerators use hot air flow to suspend sludge particles for combustion, which is suitable for the co-disposal of sludge and other solid wastes; rotary incinerators make sludge burn evenly by rotation, which is particularly suitable for high-moisture sludge; multi-stage incinerators gradually burn sludge by segmented heating, with higher combustion efficiency and lower emissions.

The main advantage of sludge incineration equipment is that it has a significant harmless effect, can completely eliminate pathogens and harmful substances in sludge, and has a good reduction effect, with very little residue after incineration. However, the investment and operation costs of incineration equipment are high, and it needs to be equipped with complete flue gas treatment equipment to ensure that emissions meet environmental protection requirements.

In addition to physical and chemical means, biological treatment of sludge is also an important treatment method. Sludge anaerobic digestion equipment decomposes organic matter in sludge through anaerobic bacteria, which can not only reduce the volume of sludge, but also produce biogas as a renewable energy source. Anaerobic digesters and upflow anaerobic sludge blanket (UASB) reactors are two common anaerobic digestion equipment. Anaerobic digesters are closed tanks suitable for stabilization of sludge, while UASB reactors are suitable for treating high-concentration organic sludge through upflow.

The advantage of anaerobic digestion equipment is that it can produce biogas while treating sludge, further realizing resource utilization, and the volume of treated sludge is significantly reduced and the stability is enhanced. Although the investment in anaerobic digestion equipment is large and the operation and maintenance are relatively complex, its economic and environmental benefits make it widely used in large-scale sludge treatment scenarios.

In addition, sludge composting equipment is a kind of equipment that mixes sludge with other organic wastes and converts it into compost through aerobic fermentation. Common types of equipment are fermentation tanks and composting machines. Fermentation tanks are suitable for small-scale sludge composting treatment, while composting machines are used in large-scale composting sites to help accelerate the fermentation process.

The biggest advantage of sludge composting equipment is its resource utilization. It converts sludge into organic fertilizer, meets environmental protection requirements and has certain economic benefits. It is suitable for gardening, agriculture and other fields. The structure of composting equipment is relatively simple, with low investment and operation costs, and is suitable for treating sludge with low moisture content.

In summary, there are many types of sludge treatment equipment with different functions. According to the nature of sludge, treatment volume and final disposal requirements, reasonable selection of equipment can achieve effective treatment and resource utilization of sludge. This can not only reduce the cost of sludge treatment, but also improve environmental benefits.

Yongle Environmental Protection is mainly engaged in the research and development, production and sales of complete sets of technical equipment for organic solid waste disposal and comprehensive utilization. Production and manufacturing, domestic waste treatment equipment, tire pyrolysis equipment, medical waste disposal equipment, hazardous waste disposal equipment, and achieve efficient and comprehensive utilization of resources through independently developed low-temperature anaerobic pyrolysis equipment technology solutions.

Tags:Sludge treatment equipment introduction and equipment features,Oil sludge treatment equipment,Yongle Group

Latest news

Latest news