Waste tires are a common solid waste in modern society, and their disposal has long plagued the fields of environmental protection and resource utilization. However, with the advancement of technology, the emergence of waste tire refining equipment has provided an efficient and environmentally friendly solution to this problem. By converting waste tires into useful resources such as fuel oil, carbon black, and steel wire, the refining technology of waste tires not only realizes the reuse of resources, but also brings significant economic benefits.

The main technological advantages of waste tire refining equipment are reflected in its resource utilization efficiency. Waste tires can be decomposed into various products such as liquid fuel oil, solid carbon black, and steel wire after pyrolysis. These products have extremely high market value. Fuel oil can be directly used for industrial boilers and power generation equipment, while carbon black is an important raw material for rubber, plastics, and other fields. Meanwhile, the steel wire extracted from waste tires can also be recycled and refined for use in the metal smelting industry. The comprehensive utilization of this resource not only reduces the harm of waste tires to the environment, but also provides strong support for the circular economy.

From an environmental perspective, waste tire refining equipment has significant advantages. Firstly, the design of the equipment adopts a fully enclosed structure, which can effectively prevent the leakage of exhaust gas, waste liquid, and waste residue during operation, and control the generation of pollution from the root. In addition, in order to further improve environmental performance, refining equipment is usually equipped with exhaust gas treatment systems, which can purify the emitted exhaust gas through processes such as desulfurization and dust removal to ensure compliance with national emission standards. Meanwhile, the combustible gases generated during the refining process of waste tires can also be recycled and utilized to provide heating energy for equipment. This self-sufficient energy cycle not only reduces the operating costs of equipment, but also reduces the consumption of external energy, making it a win-win situation.

Efficient pyrolysis process is the core of waste tire refining technology. Advanced pyrolysis technology can rapidly decompose organic components in tires under high temperature conditions, thereby obtaining high-yield fuel oil and carbon black. In this process, the improvement of thermal efficiency is particularly crucial. Modern refining equipment typically adopts multi-layer heat exchange design and intelligent temperature control system to ensure stable and efficient operation of the entire process. The precision of the temperature control system greatly improves the safety of production and avoids potential safety hazards caused by temperature control in traditional processing methods.

It is worth mentioning that the modular design of the waste tire refining equipment makes it highly adaptable. Modular design makes the installation, operation, and maintenance of equipment more convenient, and the production scale can also be flexibly adjusted according to demand. This design approach is not only suitable for large industrial enterprises, but also meets the needs of small and medium-sized processing plants. In addition, the adaptability of the equipment is reflected in its wide range of raw material processing, which can not only process waste tires, but also recycle rubber products such as waste shoe soles and conveyor belts, expanding its application fields.

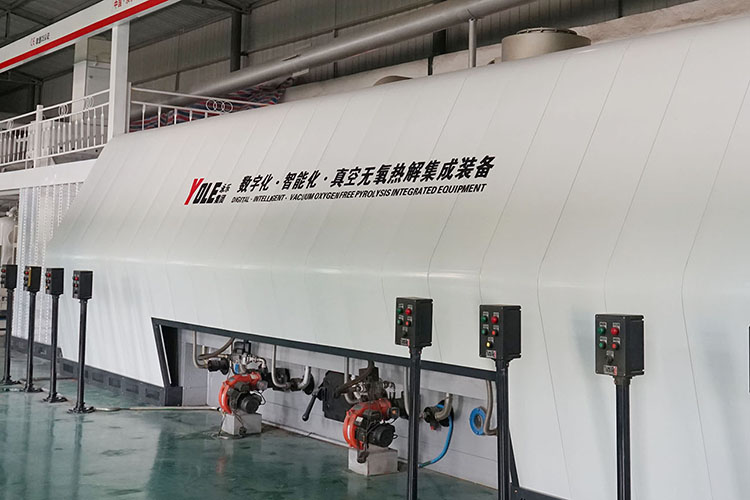

In addition to technological advantages, waste tire refining equipment also exhibits a high degree of automation. Modern refining equipment is usually equipped with intelligent control systems, which can achieve automated operation of the entire production process. The automation level of the equipment reduces the dependence on manual operation and saves labor costs. At the same time, intelligent systems can also monitor production data in real-time, providing scientific basis for further optimizing production processes. This data-driven management approach not only improves production efficiency, but also brings higher profits to the enterprise.

Overall, waste tire refining equipment is a technological innovation that integrates environmental protection, economy, and efficiency. It not only solves the problem of waste tire disposal, but also provides new possibilities for resource recycling and sustainable energy development. The equipment has achieved a win-win situation of environmental and economic benefits through efficient pyrolysis process, advanced environmental protection technology, and intelligent production mode, and is gradually becoming an important choice in the field of waste resource utilization.

Yongle Environmental Protection is mainly engaged in the research and development, production and sales of complete sets of technical equipment for organic solid waste disposal and comprehensive utilization. Production and manufacturing, domestic waste treatment equipment, tire pyrolysis equipment, medical waste disposal equipment, hazardous waste disposal equipment, and achieve efficient and comprehensive utilization of resources through independently developed low-temperature anaerobic pyrolysis equipment technology solutions.

Tags:Technological advantages of waste tire refining equipment,waste tire refining equipment,YONGLE GROUP

Latest news

Latest news