With the continuous increase in the number of cars, the amount of waste tires is also rapidly rising. The traditional methods of disposing of waste tires, such as landfilling and incineration, not only occupy a large amount of land resources, but also cause serious pollution to the environment. Therefore, finding an efficient and environmentally friendly waste tire treatment technology has become an urgent task. In this context, waste tire pyrolysis equipment has emerged as a powerful tool to solve this problem.

Waste tire pyrolysis equipment is a device that utilizes high-temperature pyrolysis technology to convert waste tires into useful products such as fuel, carbon black, and steel wire. The pyrolysis process is carried out in an anaerobic or low oxygen environment, where organic matter in the tire is decomposed into small molecules of oil and gas and solid residues through high-temperature heating. This processing method can not only effectively reduce the volume of waste tires, but also extract economically valuable by-products from them, achieving the recycling of resources.

The application scenarios of waste tire pyrolysis equipment are very wide. Firstly, the waste tire processing plant is its most direct application area. These factories specialize in collecting and processing waste tires, converting them into products such as fuel, carbon black, and steel wire through pyrolysis processes. Fuel can be used as an alternative energy source for energy production enterprises such as power plants and industrial boilers, reducing dependence on traditional fossil fuels; Carbon black can be used in the production of rubber products, inks, coatings, etc., and is an important source of raw materials for carbon black production enterprises; Steel wire can be recycled and supplied to steel production enterprises, reducing the demand for iron ore mining.

The urban waste management center is also an important application scenario for waste tire pyrolysis equipment. With the acceleration of urbanization, the pressure of urban waste disposal is increasing. If a large amount of waste tires cannot be effectively disposed of, they will occupy a large amount of landfill sites and may cause soil and groundwater pollution. Pyrolysis equipment can efficiently process these waste tires, reduce the pressure on landfills, and transform waste into useful resources, contributing to the sustainable development of cities.

Energy production enterprises have also shown strong interest in pyrolysis equipment for waste tires. The fuel produced through pyrolysis process is a high-quality alternative energy source that can alleviate energy shortages to a certain extent. Especially in areas with scarce energy resources, using the pyrolysis technology of waste tires to produce fuel can reduce dependence on external energy and improve energy self-sufficiency. In addition, the oil and gas generated by pyrolysis equipment can be further processed to produce more types of fuels and chemical products, bringing considerable economic benefits to enterprises.

Research institutions and environmental technology research and development centers are also important application sites for waste tire pyrolysis equipment. Thermal decomposition technology, as an important research direction in the field of waste tire treatment, continues to attract the attention of researchers. The relevant equipment can be used for technology optimization and new process development, promoting the development and progress of pyrolysis technology. This not only helps to improve the efficiency of waste tire treatment, but also provides reference and guidance for other types of waste treatment, promoting the comprehensive improvement of environmental protection technology.

Small recycling stations are also a potential application market for waste tire pyrolysis equipment. Although these recycling stations are relatively small in scale, they are located throughout the country and are an important component of waste tire recycling. By installing pyrolysis equipment, small recycling stations can process the recycled waste tires, turn waste into treasure, and improve economic efficiency. This can not only bring income to the recycling station, but also reduce the impact of waste tires on the environment and promote local environmental protection work.

In summary, the application scenarios of waste tire pyrolysis equipment are very extensive, covering multiple fields such as waste tire treatment plants, urban waste management centers, energy production enterprises, carbon black production enterprises, steel recycling enterprises, research institutions, and small-scale recycling stations. This technology can not only effectively solve the problem of waste tire disposal, but also transform waste into valuable products, achieving a win-win situation of economic and environmental benefits. With the continuous advancement of technology and the continuous promotion of applications, the pyrolysis equipment for waste tires will play a greater role in the future, making greater contributions to environmental protection and resource utilization.

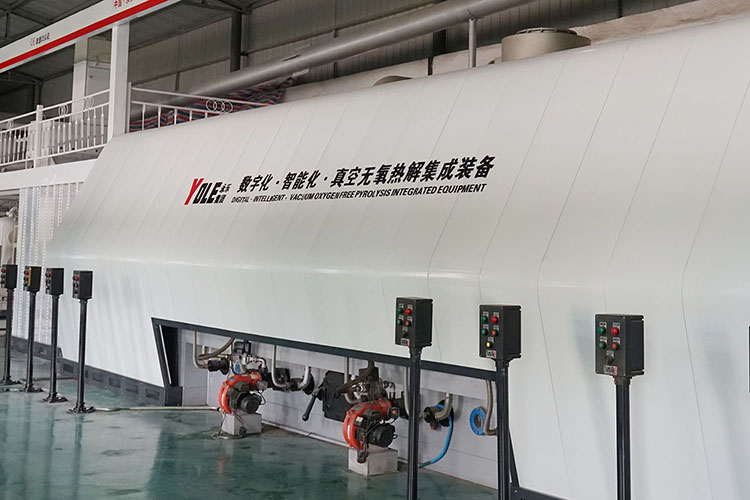

Yongle Environmental Protection is mainly engaged in the research and development, production and sales of complete sets of technical equipment for organic solid waste disposal and comprehensive utilization. Production and manufacturing, domestic waste treatment equipment, tire pyrolysis equipment, medical waste disposal equipment, hazardous waste disposal equipment, and achieve efficient and comprehensive utilization of resources through independently developed low-temperature anaerobic pyrolysis equipment technology solutions.

Tags:Application scenarios of waste tire pyrolysis equipment,Waste tire pyrolysis equipment,YONGLE GROUP

Latest news

Latest news