The initiation and operation of the waste tire refining equipment project involve various preparatory work, and the adequacy of these preparations directly affects the smooth implementation and ultimate economic benefits of the project. Firstly, market research and project feasibility analysis are the fundamental steps for project initiation. At this stage, it is necessary to conduct a detailed investigation into the sources and supply of waste tires, understand the quantity and difficulty of obtaining waste tires in the market. This includes communicating with waste tire collectors, scrap stations, and car repair shops to ensure a stable supply of raw materials. At the same time, it is necessary to analyze the market demand and potential customers of refining equipment, such as oil companies, chemical enterprises, etc., to determine the sales and market positioning of the products. Developing project budgets and profit expectations is an important task in this stage, which requires comprehensive consideration of multiple factors such as equipment procurement, site leasing, personnel salaries, and raw material costs.

In terms of site selection and preparation, choosing a suitable factory site is a prerequisite for the smooth progress of the project. The ideal factory site should be located far away from residential areas to reduce the impact on residents' lives and comply with environmental requirements, ensuring that emissions meet national standards. The site should have sufficient space to place equipment and store raw materials and finished products. In addition, the site should have a good drainage system to prevent equipment damage and production interruption caused by rainwater accumulation. At the same time, reliable power supply is also an important consideration in site selection, as refining equipment requires a large amount of power support during operation.

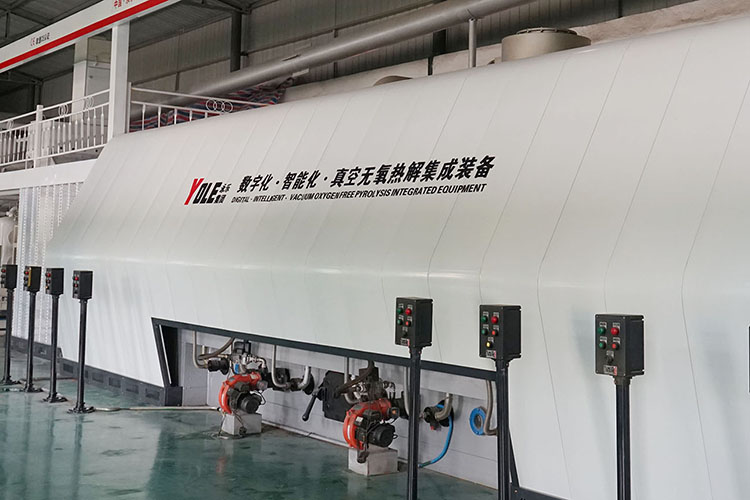

Equipment procurement and installation are key links in project advancement. It is crucial to choose a suitable refining equipment supplier, taking into account factors such as equipment quality, price, and after-sales service. The quality of equipment directly affects production efficiency and product quality, while price affects the return on investment of the project. After sales service ensures that equipment can be repaired in a timely manner in case of failure, reducing downtime. After the equipment is in place, install and debug the equipment according to the installation manual provided by the supplier to ensure that the equipment can operate normally.

In terms of raw material procurement, ensuring a stable supply channel for waste tires is the foundation for the continuous operation of the project. It is necessary to understand the purchase price and transportation cost of waste tires, establish long-term cooperative relationships with waste tire suppliers, and ensure timely supply of raw materials. A reasonable raw material procurement plan can effectively control costs and improve the economic benefits of the project.

Personnel training is also an important preparation work before the project is launched. The operation of refining equipment requires certain skills and experience, so it is necessary to recruit and train operators to ensure that they understand the operating procedures and safety precautions of the equipment. Operators should have basic knowledge of chemical engineering and equipment maintenance capabilities, and be able to perform preliminary handling in the event of equipment failure, ensuring the continuity and safety of production.

Environmental impact assessment and permit processing are necessary steps for the legal operation of projects. Conduct environmental impact assessment (EIA) in accordance with relevant local environmental regulations, and obtain relevant business licenses and environmental approvals. The environmental impact assessment report needs to provide a detailed description of the project's production process, pollutant emissions, and control measures to ensure that the project's environmental impact is within a controllable range. The project can only be officially launched after approval from relevant departments.

The formulation and implementation of safety measures are the foundation for ensuring production safety. Detailed safety operating procedures need to be developed to ensure the safety of personnel during the production process. Operators need to receive regular safety training to enhance their safety awareness and emergency response capabilities. At the same time, necessary fire-fighting equipment and emergency plans should be equipped in the factory area to prevent the occurrence of sudden accidents such as fires.

After completing the above preparation work, the project enters the trial production and adjustment stage. Conduct trial production before formal production, check the operation of equipment, adjust process parameters, and ensure the stability of the production process and the compliance of product quality. Based on the trial production results, optimize the production process and technology to improve production efficiency and product quality.

In summary, the launch and operation of the waste tire refining equipment project require comprehensive preliminary preparation work, from market research and project feasibility analysis to site selection and preparation, from equipment procurement and installation to raw material procurement, from personnel training to environmental impact assessment and permit processing, every link is crucial. Only by being fully prepared in all aspects can the project be smoothly implemented and achieve the expected economic and social benefits.

Yongle Environmental Protection is mainly engaged in the research and development, production and sales of complete sets of technical equipment for organic solid waste disposal and comprehensive utilization. Production and manufacturing, domestic waste treatment equipment, tire pyrolysis equipment, medical waste disposal equipment, hazardous waste disposal equipment, and achieve efficient and comprehensive utilization of resources through independently developed low-temperature anaerobic pyrolysis equipment technology solutions.

Tags:Preparation work before starting the tire refining equipment,Tire refining equipment,YONGLE GROUP

Latest news

Latest news