Waste rubber refining equipment is a highly innovative and environmentally friendly technology in modern industry. Through pyrolysis process, waste rubber is converted into usable fuel and other valuable by-products such as carbon black and steel wire. With the increasing awareness of environmental protection and the growing demand for resource recycling, waste rubber refining equipment has gradually become an important solution for processing waste rubber. Not only has it played a positive role in reducing environmental pollution, but it has also brought considerable economic benefits to enterprises.

The treatment of waste rubber has always been one of the environmental challenges faced. Traditional methods of treating waste rubber, such as landfilling and incineration, can cause serious pollution to the environment. Landfilling waste rubber not only occupies a large amount of land, but also leads to soil and groundwater pollution. Burning waste rubber will release a large amount of toxic and harmful gases, seriously threatening the atmospheric environment and human health. The emergence of waste rubber refining equipment provides a practical and feasible way to solve this problem.

Through waste rubber refining equipment, waste rubber can decompose in a high-temperature, oxygen free environment to produce products such as fuel, carbon black, and steel wire. Fuel can be further refined into diesel or directly used as industrial fuel, thereby reducing dependence on traditional petroleum resources. Carbon black is widely used in rubber products, plastics, coatings and other fields, and has high market value. As an indispensable part of rubber tires, steel wire can also be recycled and reused after separation treatment, becoming a raw material for steel smelting. The efficient reuse of this resource not only greatly reduces the environmental burden of waste rubber treatment, but also creates new economic growth points for enterprises.

The reason why waste rubber refining equipment has such a wide range of application prospects cannot be separated from its unique technological advantages. Firstly, the equipment adopts advanced pyrolysis technology, which is mature and stable in process. The pyrolysis process is carried out under anaerobic or hypoxic conditions, which means that waste rubber does not produce harmful substances such as dioxins during decomposition, and can minimize the negative impact on the environment. At the same time, modern waste rubber refining equipment usually has high automation characteristics, easy operation, and low maintenance costs. This is undoubtedly an important advantage for enterprises, as it reduces labor costs and improves production efficiency.

From an economic perspective, waste rubber refining equipment provides enterprises with an opportunity to convert waste into wealth. Taking the production of fuel as an example, the fuel produced by the pyrolysis of waste rubber has a high calorific value and can be used as fuel for industrial boilers, generator sets, or further processed into diesel for sale, with huge market demand. In addition, carbon black, as an important industrial raw material, is widely used in industries such as rubber, plastics, and paint, with stable prices and wide sales channels. Through this method, enterprises can not only recycle waste rubber, but also obtain considerable economic returns.

The demand for waste rubber refining products in the market is also constantly increasing. With the increasing energy shortage and environmental pressure, new energy products that replace traditional energy are becoming increasingly popular in the market. The fuel produced by waste rubber refining equipment is a highly potential alternative energy source. Especially in areas with abundant waste rubber resources, the economic benefits of waste rubber refining equipment are more prominent. By introducing devices, not only can resources be recycled, but the market demand for new energy products can also be met, gaining a competitive advantage.

In summary, waste rubber refining equipment, as an efficient, environmentally friendly, and economical solution for waste rubber treatment, is increasingly receiving attention and importance from all walks of life. Through this equipment, waste rubber can be converted into high-value products such as fuel, carbon black, and steel wire, not only creating new profit growth points for enterprises, but also playing an important role in environmental protection and resource reuse. In the context of promoting sustainable development, waste rubber refining equipment will undoubtedly become an important force in the field of waste treatment and resource utilization in the future. When selecting waste rubber refining equipment, enterprises should fully consider its technological advantages, economic benefits, and market demand to ensure maximum environmental benefits and economic returns.

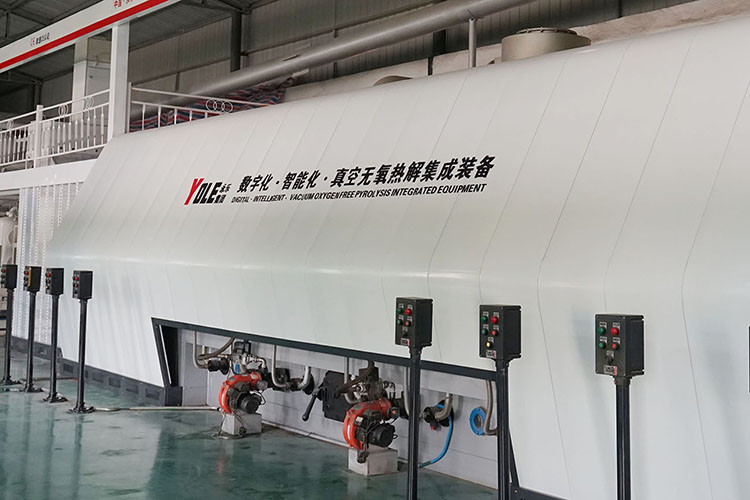

Yongle Environmental Protection is mainly engaged in the research and development, production and sales of complete sets of technical equipment for organic solid waste disposal and comprehensive utilization. Production and manufacturing, domestic waste treatment equipment, tire pyrolysis equipment, medical waste disposal equipment, hazardous waste disposal equipment, and achieve efficient and comprehensive utilization of resources through independently developed low-temperature anaerobic pyrolysis equipment technology solutions.

Tags:Composition and advantages of waste rubber refining equipment,,Yongle Group

Latest news

Latest news