With the popularity and increasing usage of electronic cigarettes, the issue of handling electronic cigarette bags and e-liquids has become increasingly prominent. Although electronic cigarettes are considered a substitute for traditional cigarettes in some cases, they also generate a large amount of waste, including used cigarette bags and residual e-liquid. If these waste materials are not handled properly, they may not only cause serious pollution to the environment, but also pose health hazards. Therefore, how to effectively handle electronic cigarette bags and e-liquids has become an urgent problem to be solved.

Firstly, one of the core processes for handling electronic cigarette waste is the waste liquid recycling equipment. Cigarette oil is one of the core components of electronic cigarettes, which contains nicotine, propylene glycol, glycerin and various essence. If these e-liquids are discharged indiscriminately, they will cause pollution to water sources and soil, and may even pose a threat to human health. Therefore, condensers and waste collectors are commonly used recycling equipment. The condenser can effectively recover volatile compounds from electronic cigarette e-liquid, which, if not treated, may cause air pollution. Meanwhile, the waste liquid collector is used to collect residual e-liquid after use, preventing it from flowing into the sewer or infiltrating into the soil. These devices can not only reduce the harm of e-liquid to the environment, but also reuse recycled materials, achieving the effect of saving resources.

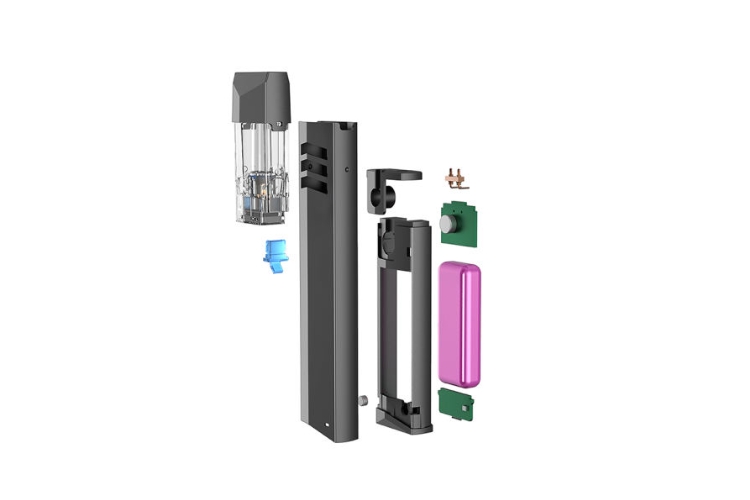

Secondly, the handling of cigarette bags is equally important. The bags of electronic cigarettes are usually made of plastic or metal. Discarding them indiscriminately not only causes visual pollution, but also has long-term negative impacts on the environment. Sorting machines and compressors are common processing equipment for this issue. The main function of the sorting machine is to separate the recyclable and non recyclable parts in the electronic cigarette bag, making the recycling process more efficient. The compressor compresses the cigarette bag to reduce its volume, making transportation and handling more convenient. In addition, plastic recycling equipment can recycle the plastic parts contained in cigarette bags through methods such as heating and melting. This process not only reduces the accumulation of plastic waste, but also provides recycled materials for the manufacturing industry, achieving resource recycling.

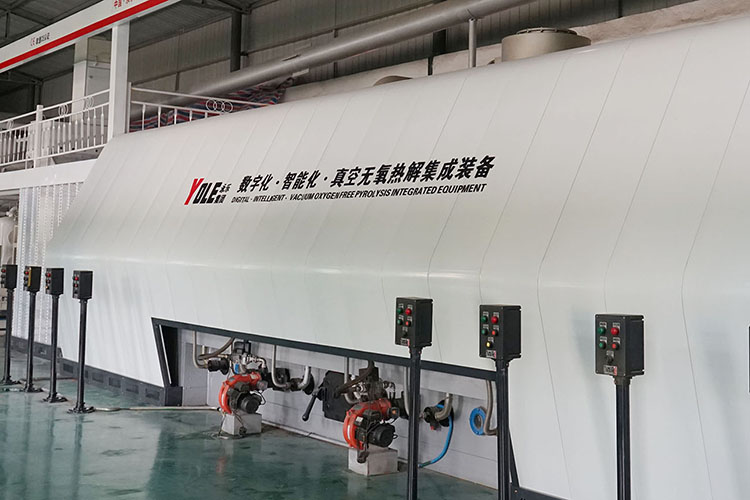

However, some electronic cigarette waste may contain harmful substances, such as e-liquids containing high concentrations of nicotine or cigarette bags made from certain specific materials. For these wastes, simple recycling or landfilling cannot completely eliminate their potential harm to the environment and human health. Incinerators have become an effective treatment method in this situation. Through high-temperature incineration, these waste materials containing harmful substances can be thoroughly decomposed, reducing the release of harmful substances. Meanwhile, modern incineration technology is equipped with advanced filtration and emission control systems, which can minimize the risk of secondary pollution to the greatest extent possible.

In addition, in order to further improve the processing efficiency of e-liquid, liquid separators are also widely used. Liquid separators can effectively separate different components from e-liquid for targeted recovery or treatment. For example, nicotine can be extracted separately and used for other purposes, while the remaining components can be treated harmlessly through other means. Through this refined processing method, not only can resources be maximally utilized, but pollutant emissions during waste disposal can also be reduced.

Finally, sewage treatment equipment also plays an important role in treating wastewater containing residual e-liquid. If certain components in electronic cigarette e-liquid enter water bodies, it can cause pollution to water quality and affect the balance of ecosystems. Wastewater treatment equipment can effectively remove harmful components from wastewater through a series of physical, chemical, and biological treatment methods, ensuring that the discharged water quality meets environmental standards. This process not only protects the water source, but also provides protection for the health of humans and other organisms.

In short, the processing of electronic cigarette bags and e-liquids requires the comprehensive application of various equipment and technologies. By using these devices reasonably, the impact of electronic cigarette waste on the environment can be effectively reduced, achieving the goals of resource recycling and environmental protection. With the continuous advancement of technology, there will be more efficient and environmentally friendly solutions for the disposal of electronic cigarette waste in the future, creating a cleaner and healthier living environment for humanity.

Yongle Environmental Protection is mainly engaged in the research and development, production and sales of complete sets of technical equipment for organic solid waste disposal and comprehensive utilization. Production and manufacturing, domestic waste treatment equipment, tire pyrolysis equipment, medical waste disposal equipment, hazardous waste disposal equipment, and achieve efficient and comprehensive utilization of resources through independently developed low-temperature anaerobic pyrolysis equipment technology solutions.

Tags:Detailed introduction of electronic cigarette bag e-liquid processing equipment,,Yongle Group

Latest news

Latest news