With the rapid development of the global automotive industry, the number of waste tires is also rapidly increasing. Waste tires not only occupy a large amount of land resources, but also cause serious pollution to the environment. However, waste tires contain abundant organic matter and metals, which have high recycling value. As an advanced treatment technology, the pyrolysis equipment for waste tires not only effectively solves the environmental pollution problem of waste tires, but also converts them into high value-added resources, achieving the resource utilization and harmless disposal of waste.

The pyrolysis equipment for waste tires consists of multiple key components, each of which plays an important role in the entire treatment process. The feeding system, including conveyors and crushers, is used to cut, crush, and transport waste tires to the pyrolysis reactor. The conveyor transports large pieces of tires to the crusher for initial crushing, and then further processes them to achieve a particle size suitable for pyrolysis. The pyrolysis reactor is the core part of the equipment, usually using a rotary kiln or fixed bed reactor. Under anaerobic or anaerobic conditions, the reactor heats waste tires at high temperatures to decompose them into products such as oil and gas, carbon black, and steel wire. The heating system includes a burner or an electric heating device, which is used to provide the high-temperature environment required for pyrolysis. Modern pyrolysis equipment often adopts efficient and energy-saving heating methods to ensure energy utilization during the reaction process. The oil and gas generated by the condensation system during the pyrolysis process are cooled by the condensation system and converted into liquid oil products. The condenser is a critical component, usually cooled by water or air. The gas treatment system processes the non condensable gases generated from pyrolysis to ensure emissions meet standards. It includes dust collectors, desulfurization devices, etc., which can effectively remove harmful gases and particles. The solid treatment system is used to treat solid residues such as carbon black and steel wire generated after pyrolysis. Carbon black can be further processed into industrial products, while steel wire can be recycled and reused.

The basic principle of pyrolysis of waste tires is to decompose them into reusable resources through high-temperature pyrolysis. Under anaerobic conditions, waste tires are heated to 300-700 degrees Celsius and undergo pyrolysis reactions, generating oil and gas, carbon black, and steel wire. Firstly, the waste tires are crushed and sent to the pyrolysis reactor through a conveying system. In the reactor, the tire is heated to high temperature and begins to decompose under anaerobic conditions. Subsequently, the oil and gas generated during the pyrolysis reaction process are cooled through a condensation system and liquefied into oil products. These oil products can be used as industrial fuels or further refined into high value-added products such as gasoline and diesel. Uncondensed gas is purified through a gas treatment system to remove harmful components and ensure emissions meet standards. Finally, the carbon black and steel wire produced by pyrolysis are separated and recovered through a solid treatment system. Carbon black can be used as an industrial raw material for manufacturing rubber products, pigments, etc., while steel wire can be recycled for use in the metallurgical industry.

The pyrolysis technology of waste tires has significant advantages. Firstly, the pyrolysis technology of waste tires can effectively reduce the environmental pollution caused by waste tires, and avoid the waste of land resources and environmental damage caused by tire landfill. Secondly, the harmful gases generated during the pyrolysis process are discharged after treatment, which meets environmental standards and reduces the impact on air quality. Through pyrolysis technology, the organic matter and metals in waste tires have been fully utilized. The oil products, carbon black, and steel wires produced by pyrolysis have high economic value and can be used as industrial raw materials to re-enter the production cycle and achieve sustainable utilization of resources. The investment return rate of waste tire pyrolysis equipment is relatively high. The oil produced by pyrolysis can be used as fuel or further processed into high value-added products, and the recycling and utilization of carbon black and steel wire also brings considerable economic benefits. In addition, with the strengthening of environmental protection policies and the intensification of resource shortages, the market demand for waste tire pyrolysis technology will continue to increase, with broad development prospects.

With the advancement of technology and the enhancement of environmental awareness, the pyrolysis technology of waste tires has received widespread attention and application worldwide. In the future, with the continuous innovation of technology and the optimization and upgrading of equipment, the pyrolysis technology of waste tires will develop towards a more efficient, environmentally friendly, and economical direction. By introducing new materials, processes, and equipment, the pyrolysis efficiency and product quality can be further improved. For example, using catalytic pyrolysis technology can lower the pyrolysis temperature, improve oil production and quality. Applying advanced technologies such as the Internet of Things, big data, and artificial intelligence to achieve intelligent management and control of pyrolysis equipment, improving production efficiency and equipment operation stability. Build a circular economy model that combines pyrolysis of waste tires with other waste treatment technologies to achieve comprehensive utilization of various wastes and further improve resource utilization and economic benefits.

The pyrolysis equipment for waste tires, as an innovative technology for environmental protection and resource reuse, has broad development prospects. Through continuous technological innovation and equipment optimization, the pyrolysis technology of waste tires will play an important role in solving the pollution problem of waste tires, promoting sustainable resource utilization, and achieving the development of circular economy. In the future, we should continue to increase the research and promotion of pyrolysis technology for waste tires, making greater contributions to environmental protection and resource reuse.

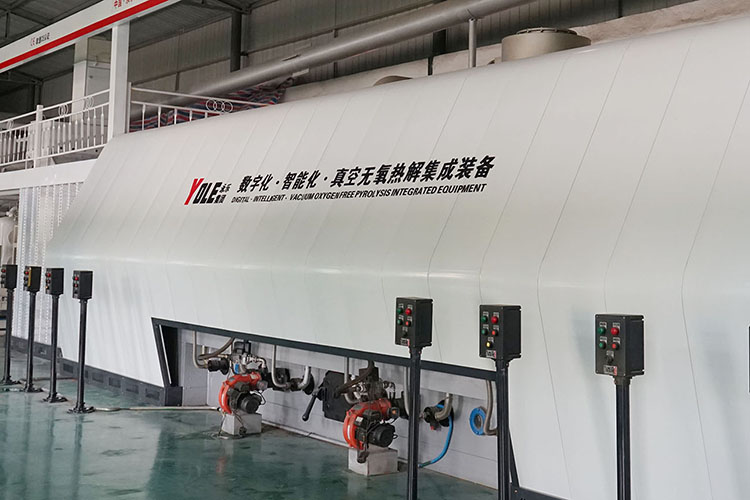

Yongle Environmental Protection is mainly engaged in the research and development, production and sales of complete sets of technical equipment for organic solid waste disposal and comprehensive utilization. Production and manufacturing, domestic waste treatment equipment, tire pyrolysis equipment, medical waste disposal equipment, hazardous waste disposal equipment, and achieve efficient and comprehensive utilization of resources through independently developed low-temperature anaerobic pyrolysis equipment technology solutions.

Tags:Detailed introduction of pyrolysis equipment for waste tires,Waste tire pyrolysis equipment,YONGLE GROUP

Latest news

Latest news