Scrap tires are one of the common waste materials in modern society, and their quantity has been increasing year by year with the development of the automotive industry and the increase in car ownership. The disposal of waste tires has become a global environmental challenge. The traditional disposal methods for waste tires mainly include landfill and incineration, but these methods not only occupy a large amount of land resources, but also cause serious environmental pollution. In order to solve this problem, environmentally friendly refining equipment with waste tires has emerged. This article will explore in detail the use and importance of environmentally friendly refining equipment using waste tires.

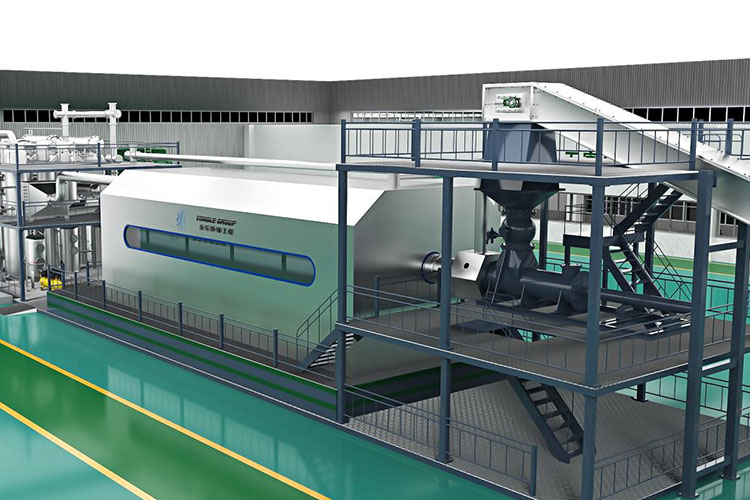

One of the main functions of environmentally friendly refining equipment for waste tires is to recycle and reuse waste tires. Through high-temperature cracking technology, waste tires can be decomposed into various useful products such as fuel oil, carbon black, and steel wire. High temperature cracking is a thermochemical reaction process in which organic matter in waste tires undergoes pyrolysis in high temperature and anaerobic environments, generating fuel oil and gas, while leaving solid products such as carbon black and steel wire. In this way, not only can waste tires reduce environmental pollution, but they can also be converted into renewable resources, achieving resource recycling.

The waste tire refining equipment converts organic substances in waste tires into fuel oil through high-temperature cracking technology. This fuel oil is a high energy density liquid fuel that can be used as fuel for industrial boilers, generators, and heavy machinery. Against the backdrop of global energy scarcity and increasing scarcity of oil resources, fuel oil converted from waste tires provides an alternative energy source to traditional oil. Waste tire refining equipment can not only reduce dependence on petroleum resources, but also provide an economical, efficient, and environmentally friendly energy option for industrial production.

Waste tires and environmentally friendly refining equipment can also produce carbon black. Carbon black is an important industrial raw material widely used in industries such as rubber products, inks, coatings, and plastics. Carbon black produced through waste tire refining equipment has high purity and good physical and chemical properties, which can replace some traditional carbon black production processes and reduce production costs. In addition, carbon black produced from waste tires also has environmental advantages, reducing the environmental pollution caused by traditional carbon black production processes.

Waste tires contain a large amount of steel wire, which can be separated and recycled during the high-temperature cracking process. The recycled steel wire can be used as a raw material for steel production, re-entering the industrial production cycle and saving steel resources. The recycling of steel wires through environmentally friendly refining equipment using waste tires not only reduces reliance on primary ore resources, but also reduces waste of steel resources, achieving the goal of waste resource utilization.

If waste tires are not treated and left to accumulate, they will occupy a large amount of land resources and are difficult to degrade in the natural environment, leading to long-term environmental pollution. The landfill of waste tires not only occupies valuable land resources, but may also lead to pollution of groundwater and soil. Burning waste tires will release a large amount of harmful gases, polluting the air. The environmentally friendly refining equipment for waste tires can effectively convert waste tires into fuel oil, carbon black, and steel wire through high-temperature cracking technology, reducing the accumulation of waste tires and reducing environmental pollution.

Waste tires and environmentally friendly refining equipment are also of great significance in resource conservation. By recycling and reusing resources from waste tires, it is possible to reduce the exploitation and consumption of natural resources and protect the natural environment. The organic matter in waste tires is cracked and converted into fuel oil, replacing some petroleum resources and reducing dependence on oil extraction. The steel wire contained in waste tires can be recycled to replace some steel resources, reducing the demand for iron ore mining. In addition, the produced carbon black can also replace some of the raw materials in traditional processes, saving chemical resources.

Waste tires and environmentally friendly refining equipment not only have important significance in resource utilization and environmental protection, but also can promote sustainable economic development. The application of environmentally friendly refining equipment with waste tires can create new economic growth points, increase employment opportunities, and drive the development of related industries. At the same time, the recycling and resource utilization of waste tires are in line with the development concept of circular economy, promoting the recycling of resources and sustainable economic development.

In summary, waste tires and environmentally friendly refining equipment are of great significance in waste resource utilization, environmental protection, and energy reuse. Through high-temperature cracking technology, waste tires can be converted into fuel oil, carbon black, and steel wire, achieving resource recycling, reducing environmental pollution, and conserving natural resources. Waste tire environmentally friendly refining equipment is not only an effective waste treatment technology, but also an important means to promote sustainable economic development. In the future, with the continuous progress of technology and the continuous promotion of applications, waste tire environmentally friendly refining equipment will play a more important role, making greater contributions to achieving green environmental protection and sustainable development.

Yongle Environmental Protection is mainly engaged in the research and development, production and sales of complete sets of technical equipment for organic solid waste disposal and comprehensive utilization. Production and manufacturing, domestic waste treatment equipment, tire pyrolysis equipment, medical waste disposal equipment, hazardous waste disposal equipment, and achieve efficient and comprehensive utilization of resources through independently developed low-temperature anaerobic pyrolysis equipment technology solutions.

Tags:The Use and Social Value of Waste Tire Environmental Refining Equipment,Waste tire refining equipment,YONGLE GROUP

Latest news

Latest news