Efficient treatment of medical waste is an important task in the modern medical and health industry. With the gradual increase in the types and treatment standards of medical waste, the traditional single treatment method can no longer meet the growing waste treatment needs of hospitals. Medical waste pyrolysis equipment, as an efficient and environmentally friendly treatment technology, has gradually become the mainstream choice in the market because it can simultaneously treat multiple types of medical waste. However, how to select an efficient medical waste pyrolysis equipment, especially one that can simultaneously treat five major types of medical waste (infectious, pathological, pharmaceutical waste, injury waste and ordinary medical waste), not only depends on the technical performance of the equipment, but also needs to be accurately matched according to the actual needs, types of waste and treatment volume of different medical institutions.

First of all, the type and nature of medical waste must be considered when choosing a suitable pyrolysis equipment. Medical waste is highly complex and usually includes infectious waste, pathological waste, pharmaceutical waste, injury waste and ordinary medical waste. The composition and treatment requirements of each type of waste are different, so the equipment needs to have flexible processing capabilities and corresponding technical support. For example, the treatment of infectious waste requires higher temperatures, and usually requires sterilization and decomposition at high temperatures; pathological waste requires special safety treatment to prevent the spread of pathogens; pharmaceutical waste may contain harmful chemicals, and equipment that can effectively decompose toxic components needs to be selected; and damage waste needs to be improved through pre-treatment processes such as crushing to improve pyrolysis efficiency.

Therefore, a pyrolysis device that can simultaneously treat five major types of medical waste must have multiple treatment modes, and can automatically adjust pyrolysis parameters such as temperature, time, and oxygen supply according to the characteristics of different wastes. In addition, the equipment's automated control system needs to be able to accurately control various parameters during the waste delivery and pyrolysis process to ensure that each type of waste is treated most appropriately. This design not only improves the equipment's processing efficiency, but also greatly reduces the complexity of manual operation, ensuring the safety and efficiency of the treatment process.

In addition to the diversity of waste types, waste processing capacity is also an important consideration when selecting a model. The amount of waste generated by medical institutions every day varies greatly, especially in large hospitals or medical centers, where the amount of waste generated is much higher than that of ordinary clinics or grassroots hospitals. Therefore, when purchasing pyrolysis equipment, it is necessary to select the appropriate processing capacity based on the amount of waste processed by the medical institution. The processing capacity of the equipment is usually measured in tons/day or kilograms/hour. Users should make reasonable selections based on the actual amount of garbage generated and the processing efficiency of the equipment. If the amount of medical waste to be processed is large, it is recommended to choose continuous pyrolysis equipment, which can operate uninterruptedly around the clock to meet large-scale garbage processing needs. For small medical institutions, equipment with smaller processing capacity and suitable for intermittent processing can be selected.

While ensuring that the equipment processing capacity and technology meet the requirements, environmental performance is also a factor that cannot be ignored in the selection. With the increasingly stringent environmental regulations, the emission standards of medical waste treatment equipment are becoming higher and higher. Harmful gases generated during pyrolysis, such as dioxins, nitrogen oxides, sulfides, etc., must be treated by efficient exhaust gas purification devices. This is not only a necessary condition to ensure the compliance of the equipment, but also directly affects the social responsibility and market competitiveness of the equipment. Therefore, it is particularly important to choose equipment with advanced exhaust gas treatment technology. For example, the use of multi-stage filtration technology, catalytic reduction technology, dry and wet dust removal and adsorption tower and other combined technologies can effectively remove harmful components in the exhaust gas and ensure that the equipment emissions meet national or local environmental protection standards.

On the other hand, the energy efficiency and economy of the equipment are also factors that must be considered when selecting. The operation of pyrolysis equipment consumes a lot of energy. Therefore, how to effectively reduce energy consumption and improve energy utilization efficiency is a key indicator when selecting equipment. Some high-end pyrolysis equipment is equipped with a waste heat recovery system. By recovering the heat generated during the treatment process, it can provide auxiliary energy for the equipment and even supply other energy needs of the hospital (such as heating, hot water, etc.). This energy-saving design not only reduces the operating cost of the equipment, but also brings higher economic benefits to the hospital.

Finally, the selection of medical waste pyrolysis equipment also needs to consider the safety and ease of operation of the equipment. The medical waste treatment process may involve dangerous factors such as high temperature and pressure. Therefore, the equipment needs to have complete safety protection measures, including automatic monitoring system, emergency shutdown function, temperature and pressure alarm device, etc. In addition, the operation interface of the equipment should be simple and easy to understand, with a high degree of automation to reduce the possibility of human operation errors.

In summary, choosing an efficient medical waste pyrolysis equipment, especially equipment that can simultaneously process five major types of medical waste, requires comprehensive consideration of multiple factors such as waste type, processing capacity, environmental protection requirements, energy efficiency and safety. With the continuous advancement of technology, more and more high-efficiency pyrolysis equipment that meet diverse needs have appeared on the market. Medical institutions can choose the most suitable type of equipment according to their actual situation, so as to achieve the goal of efficient and environmentally friendly medical waste treatment.

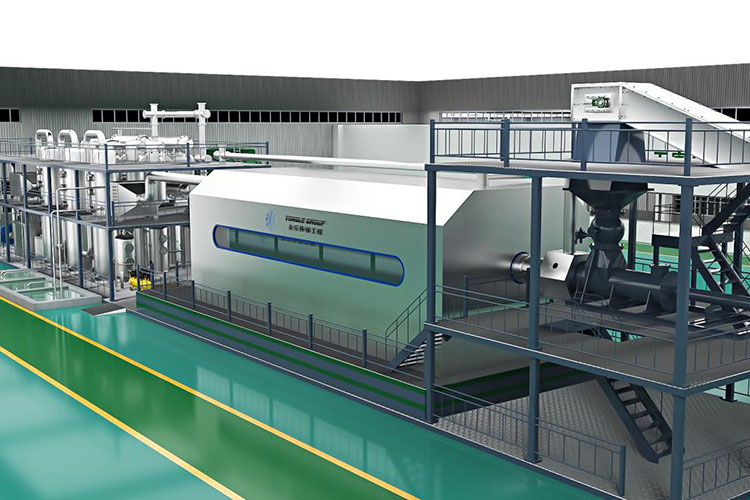

Yongle Environmental Protection is mainly engaged in the research and development, production and sales of complete sets of technical equipment for organic solid waste disposal and comprehensive utilization. Production and manufacturing, domestic waste treatment equipment, tire pyrolysis equipment, medical waste disposal equipment, hazardous waste disposal equipment, and achieve efficient and comprehensive utilization of resources through independently developed low-temperature anaerobic pyrolysis equipment technology solutions.

Tags:How to select medical waste pyrolysis equipment for efficient treatment,medical waste pyrolysis equipment for efficient treatment,YONGLE GROUP

Latest news

Latest news