Plastic refining equipment is a device that converts waste plastics into reusable fuel oil through high-temperature cracking process, and is widely used in the fields of waste plastic treatment and resource utilization. The equipment is mainly concentrated in areas with high waste plastic production, and its production process and application have important social value in improving the environment and increasing resource utilization.

The production process of plastic refining equipment mainly includes several key steps, including plastic pretreatment, high-temperature cracking, separation and cooling, oil and gas purification, and finished product storage. Firstly, the pre-treatment of waste plastics includes classification, cleaning, and crushing, and sending suitable plastic raw materials into the cracking reactor. By using a heating device to raise the temperature inside the reaction vessel to 300-600 degrees Celsius, waste plastics are thermally decomposed into oil and gas and a small amount of solid residue in an anaerobic or microaerophilic environment. The generated oil and gas are then converted into liquid fuel oil through a condensation system, and the remaining non condensed gas can be recovered for use in the heating system of the equipment, thereby achieving energy recycling. Finally, the finished fuel oil is filtered and purified before being stored for future use.

The social value of plastic refining equipment is mainly reflected in the following aspects:

1. Reduce plastic pollution

With the increase of plastic consumption, the recycling and disposal of waste plastics has become a major environmental issue. Plastic refining equipment reduces land waste and harmful gas emissions caused by landfilling and incineration by utilizing waste plastics as resources, providing an effective way for surrounding areas to dispose of plastic waste.

2. Promote resource recycling and utilization

The main component of plastic raw materials is petroleum. Plastic refining equipment can convert waste plastics back into fuel oil, thereby extending the life cycle of plastics and reducing dependence on natural petroleum resources. This closed-loop utilization model not only conforms to the concept of sustainable development, but also provides an alternative energy source for resource scarce areas.

3. Create economic benefits

This equipment is usually installed around industrial parks or urban waste treatment centers where plastic waste is concentrated, which can reduce the cost of raw material transportation and bring new employment opportunities and economic income to the local area. The converted fuel oil can be used as industrial boiler fuel or further refined into diesel, with broad market application prospects.

4. Technology Promotion and Regional Impact

In the surrounding areas of equipment, the introduction of technology often drives the development of related environmental protection industries. For example, optimization of waste plastic classification and recycling system, progress in related machinery manufacturing industry, etc. This intensive environmental protection technology model provides a good demonstration effect for surrounding cities and industrial areas, further promoting the popularization of environmental awareness.

Overall, the application of plastic refining equipment not only achieves efficient conversion of waste plastics into fuel oil technically, but also demonstrates enormous potential for environmental protection and economic development at the societal level, providing a feasible solution for regional environmental protection and resource management.

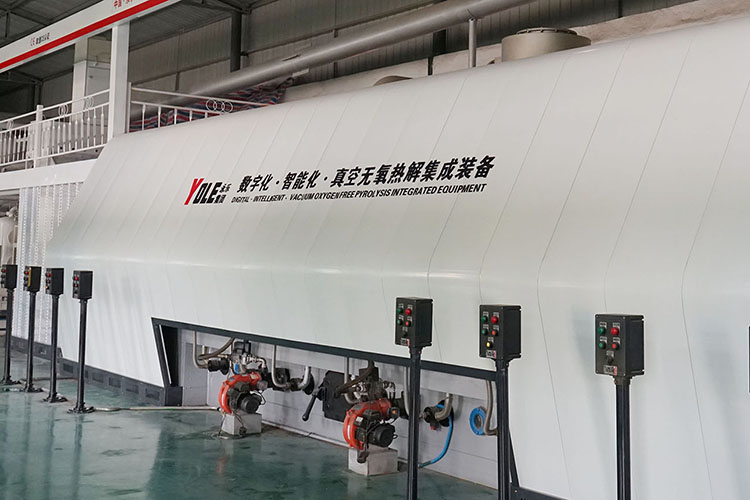

Yongle Environmental Protection is mainly engaged in the research and development, production and sales of complete sets of technical equipment for organic solid waste disposal and comprehensive utilization. Production and manufacturing, domestic waste treatment equipment, tire pyrolysis equipment, medical waste disposal equipment, hazardous waste disposal equipment, and achieve efficient and comprehensive utilization of resources through independently developed low-temperature anaerobic pyrolysis equipment technology solutions.

Tags:Production process and social value of plastic refining equipment,plastic refining equipment,YONGLE GROUP

Latest news

Latest news