Waste tire refining equipment is an efficient and environmentally friendly technical device for processing waste tires. With the increasing attention to the resource utilization of waste tires, waste tire refining equipment has become an important equipment in the environmental protection industry. These devices can convert waste tires into valuable resources such as fuel oil, carbon black, and steel wire through high-temperature cracking. According to the different working modes and degrees of automation of the equipment, there are various types of waste tire refining equipment, and the price range also varies greatly. This article will provide a detailed introduction to the models and prices of different types of waste tire refining equipment.

Firstly, the main types of waste tire refining equipment can be divided into three types: intermittent equipment, semi continuous equipment, and fully continuous equipment. Their working principles and production efficiency differ significantly, and their applicable production environments and requirements are also different.

Intermittent refining equipment is the most basic and common type. Its working method is to periodically process waste tires, which involves feeding, heating, cracking, and draining in batches until one cycle is completed before starting the next cycle. Due to its simple structure, easy operation, and low investment cost, this device is very suitable for small-scale production or early-stage investors. The main characteristic of intermittent refining equipment is relatively small processing capacity, which is usually suitable for small enterprises with small annual waste tire processing capacity. In terms of price, the price of intermittent refining equipment is usually between 200000 and 300000 RMB, and the specific price varies depending on the specifications and production capacity of the equipment. For equipment with a daily processing capacity of around 5 tons, the price fluctuates roughly within this range. For some additional configurations such as highly automated feeding systems or oil discharge systems, prices may slightly increase.

Compared to intermittent equipment, semi continuous refining equipment has significantly improved performance and efficiency. It combines the characteristics of intermittent and continuous feeding, and can achieve the functions of continuous feeding and timed oil discharge, reducing equipment downtime and improving production efficiency. Semi continuous refining equipment is usually suitable for medium-sized waste tire processing enterprises, which can improve production efficiency and reduce labor costs to a certain extent. Compared with intermittent equipment, the price of semi continuous equipment is higher, generally around 500000 RMB. The specific fluctuation of prices will vary depending on the automation level of the equipment, the feeding capacity of the equipment, and the different manufacturers. In addition, semi continuous equipment usually requires higher technical support and maintenance services, so the later operation and maintenance costs need to be considered when purchasing.

The fully continuous refining equipment is currently the most advanced type of waste tire refining equipment on the market. The biggest feature of this equipment is that it can achieve a fully automated production process, which not only enables continuous feeding, cracking, and oil discharge throughout the entire process, but also continuously outputs the final fuel oil and carbon black products during the operation of the equipment. The fully continuous equipment is very suitable for large-scale waste tire processing enterprises, especially those that require long-term stable production. The processing capacity of fully continuous equipment is usually large, which can meet the demand of processing thousands of tons of waste tires annually. Due to its high degree of automation and production efficiency, the price of such equipment is relatively expensive, usually above 1 million yuan, and can even reach several million yuan or more. The specific price of the equipment will be affected by production capacity, technical configuration, automation level, and additional facilities such as exhaust gas treatment equipment, dust removal systems, etc. Although the initial investment of fully continuous equipment is relatively large, its efficient production capacity and lower labor costs result in a higher return on investment in long-term operation.

In addition to these three mainstream refining equipment, there is also a special type of waste tire refining equipment - skid mounted refining equipment. This equipment arranges the entire refining system in a standard container for easy transportation and installation. Skid mounted equipment is usually suitable for enterprises that have high requirements for equipment mobility, or some start-up companies. The production capacity of skid mounted equipment is generally small, usually processing 1 to 3 tons of waste tires per day. In terms of price, the price of modular equipment is usually between 200000 and 500000 RMB, and the specific price varies depending on the model and configuration of the equipment.

Overall, the price differences of different models of waste tire refining equipment are mainly reflected in the degree of automation, production capacity, and technical configuration of the equipment. Intermittent equipment has a lower price and is suitable for small businesses or experimental projects; Semi continuous equipment is an ideal choice for medium-sized enterprises, with certain production efficiency and cost advantages; And fully continuous equipment is suitable for large-scale production. Although the initial investment is relatively high, its efficient production capacity and long-term investment return make it the first choice for large enterprises. Skid mounted equipment is more suitable for small-scale enterprises that require equipment mobility or small projects that require flexible production. When purchasing equipment, enterprises should make reasonable choices based on their own needs, budget, and market prospects.

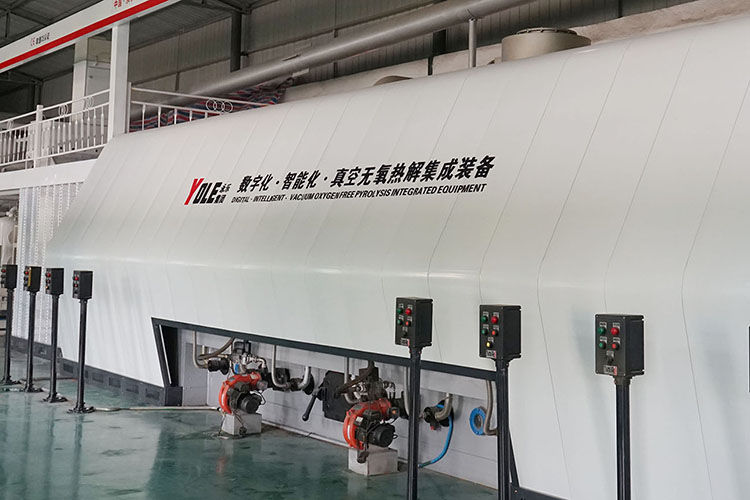

Yongle Environmental Protection is mainly engaged in the research and development, production and sales of complete sets of technical equipment for organic solid waste disposal and comprehensive utilization. Production and manufacturing, domestic waste treatment equipment, tire pyrolysis equipment, medical waste disposal equipment, hazardous waste disposal equipment, and achieve efficient and comprehensive utilization of resources through independently developed low-temperature anaerobic pyrolysis equipment technology solutions.

Tags:Types and prices of waste tire refining equipment models,waste tire refining equipment,YONGLE GROUP

Latest news

Latest news